Casting slugs from Linotype Mats in the Nebitype

- A Nebitype-Linotype Stick holder with a Linotype Stick Holder microswitch assembly*

- A Nebitype-Linotype Stick

- A Nebitype-Linotype casting plate for the pointsize of font to be cast. (6-24pt)

- Sufficient linotype mats to fill the stick (i.e. 42ems-worth)

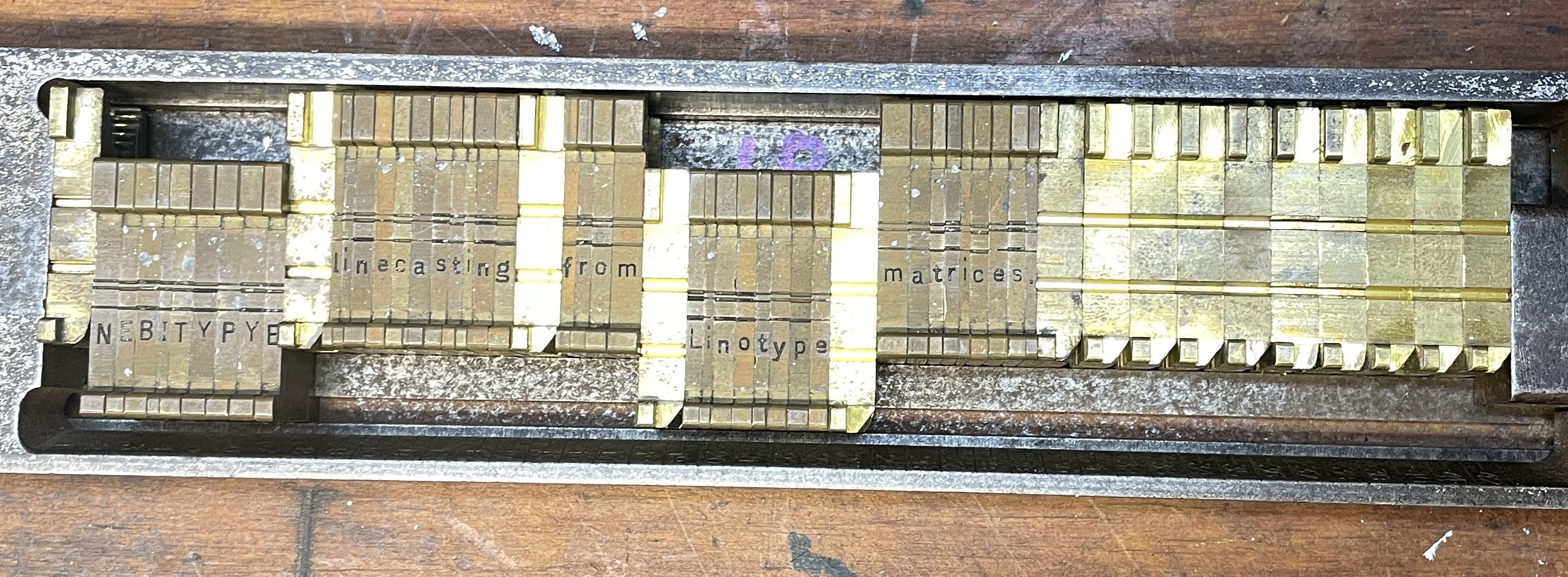

The Linotype Stick (left) and Linotype Stick Slide for 18pt (right). Each Type size has its own corresponding slide, the milled out section in the Stick Slide being the height of the type concerned. The slide is slid into the bottom of the stick and the mats set into the slide, casting side down. Note the two narrow slots and single large slot which permit the mounting of the mats in the normal or alternate position. (See image below for illustration of how this works in practice.)

The stick is assembled for casting by:

- Sliding the casting plate into the linotype stick. The stick has a two grooves milled into the inside edges of the back to receive the slide.

- Inserting mats into the stick (see composing below)

- Locking up the stick

- Changing the stick holder on the Nebitype

- Inserting the stick into the stick holder and pressing the start button

Composing

The casting plate has three mat positioning grooves mill along the inside, two narrow and one wide. These grooves correspond to the 'ears' or 'lugs' of linotype mats. The choice of narrow groove will determine whether the normal typeface or alternative typeface is cast.

In addition to the mat positing grooves there also is a casting slot milled through the plate which is where the type metal is injected from the mould through to the mats.

The a Nebitype-Linotype stick with mats mounted in both the normal and alternative face positions

There are multiple casting plates, one for each point size that can be cast. (i.e. 6, 8, 10, 12, 14, 16, 18 & 24pt), the slot width matching the point size of the type being cast. I am unsure as to whether there were larger casting plates than 24pt; that was all that came with my Nebitype

The slot width dictates the size of the metal underpinning the letter, so the correct plate size should be used for each point size cast.

(The "depth" of the underpinning the slug typeface will be the same as the depth of the casting plate.)

Inserting the mats

Mats are inserted, typeface down (facing the casting-slot), with the small lug of the mat inserted into one of the two narrow grooves. The larger lug will fit into the wide groove regardless of which small groove is used. The small groove chosen determines whether the normal or auxiliary glyph is cast.

Nebitype sticks don't use linotype/intertype space bands and so manual spacing must be performed with mats. If no space mats are available a normal letter mat could be reversed so that the reference side is facing the casting slot. Once the stick is full it should be tightened with the locking knob and inserted into the stick holder to be cast. The lugs of the matrices are a fairly snug fit into the casting plate, so once the locking screw has been tightened it's unlikely that the casting plate would slide off the stick.

Casting

On the Nebitype NTC series the Linotype microswitches do not seem to align with anything that will actuate them. This may be as a result of modifications to the machine or because the linotype casting assemblies were manufactured for a later model. The microswitches can be adjusted for a larger gap, but the possibility of a squirt increases if the switches were able to actuate before the stick is in the proper casting position.

The stick mounted in the linotype stickholder in the machine. The middle of the picture shows the casting slot, which will be locked up against the mouthpiece (with the upside down 4 on it) when the elevator lifts them up to the mouthpiece and clamps them down. Note this is a 12 point stick with a 12pt casting slot milled along the face. Immediately behind this slot are the linotype mats, locked into position with the small locking knob, left centre.